Our Wikipedia, method of marking: sandblasting

This is a surface marking method, similar to laser surface engraving, which involves removing material from the surface of the figurine and matting it. The material in the sandblasted area has a depression, the size of which depends on the length and intensity of sandblasting in a given area. The surface has a matte structure that can be clearly felt under the finger.

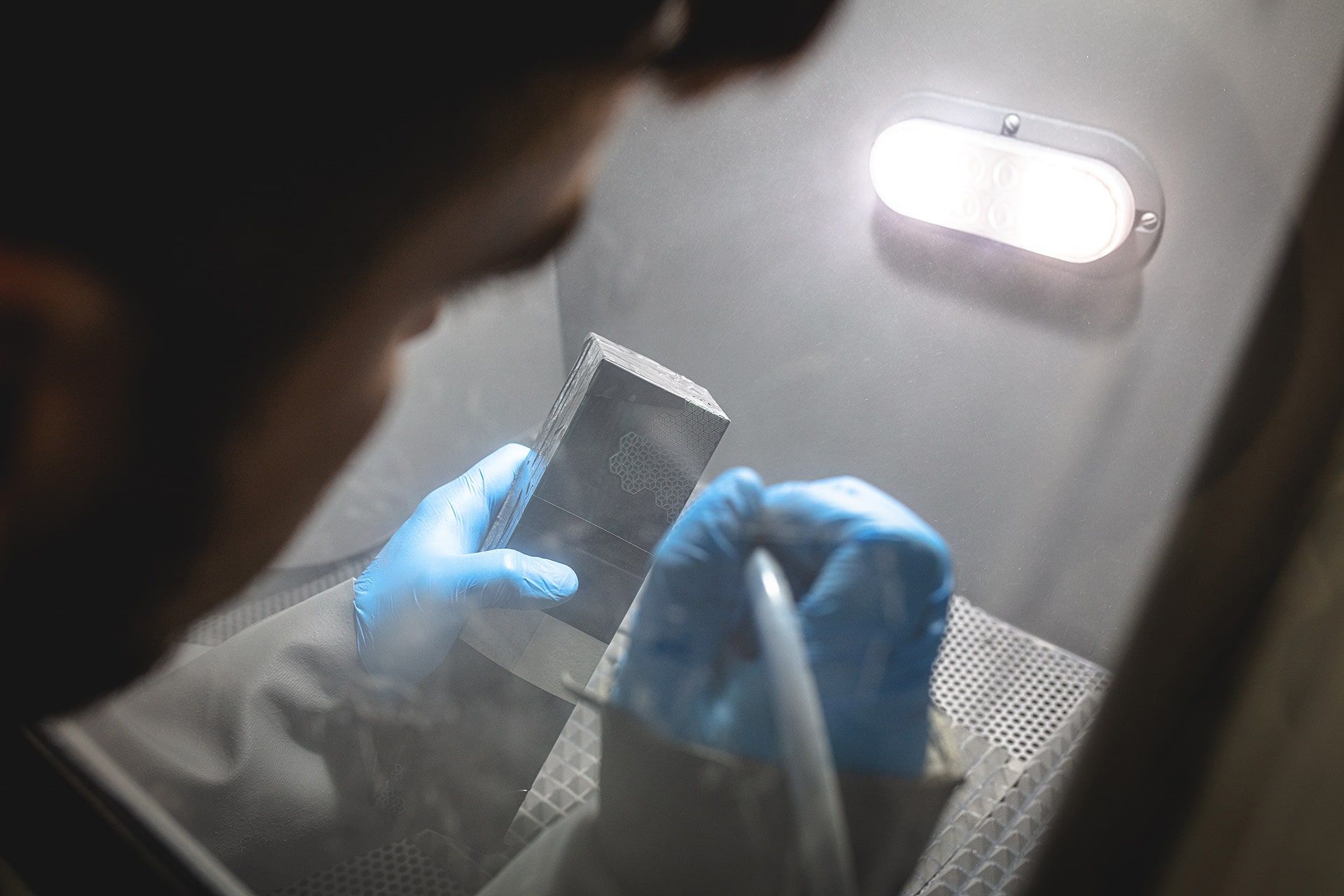

Sandblasting is one of the more versatile methods, but it is practically used in most cases for glass. Sandblasting on glass gives great possibilities for its processing through the possibility of carving in glass.

The most common and popular examples of sandblasted surfaces are matte glasses or mugs with company logos. Sandblasting provides great freedom in creating glass figurines, especially when combined with other methods of glass individualization.

By holding the sandblasting nozzle in one place for a longer time, we can adjust the depth of sandblasting, and thus, for example, create a pseudo-three-dimensional effect, which gives the best effect in sandblasting figurines from their back surfaces. Then, looking from the front, we can see letters or logos almost carved into the glass.

The prepared element is already ready for further use. Sandblasting itself gives an interesting visual effect, and we can additionally apply colored marking to sandblasting. We can do this in two ways:

a) With UV printing

Then, in addition to sandblasting, we can fill the sandblasted area with any color or tonal gradient, which is not possible with filling with paint. The sandblasted surface is then subjected to UV printing. Printing on a matte surface makes it much more durable than printing on a flat polished glass surface, and also enhances the surface, giving it a unique look and aesthetics.

b) Filled with paint

The surface that is sandblasted and filled with paint is characterized by high mechanical and chemical durability. It is not susceptible to moisture, and its biggest advantage is the possibility of using metallic paints. The effect obtained in this process, unlike UV printing, gives a metallic shine mainly in several basic colors such as gold, bronze, or silver.

It can be used, for example, in the case of marking figurines where we want to differentiate the winner of the 1st place with a gold color, the 2nd place with a silver color, and the 3rd place with a bronze color.

Filling with paint or painting glass surfaces gives a lot of possibilities for the final look of the figurine. It is also one of the most important techniques for refining the surface of figurines so that they look very exclusive and prestigious. Particularly phenomenal are realizations in which we additionally use CO2 laser engraving as the final stage, which applies graphic motifs to the paint surface.

Deep sandblasting

Deep sandblasting is achieved through the standard sandblasting process, but it is done significantly longer. The sandblasting time determines the depth of the incision. In order to achieve an interesting spatial effect, sandblasting must be done at a depth of at least several millimeters. Deep sandblasting looks best when viewed from the other side of the glass (so the sandblasting must be done in a mirrored reflection on the back surface of the glass). The viewer of the figurine has the impression of placing a three-dimensional object inside the glass. Deep sandblasting can also be used for artistic sculpting in glass.

Finishing glass and edges

Sandblasting is also useful for glass processing without giving specific patterns. The two basic uses of the sandblaster are finishing edges and frosted glass.

Finishing the edges is useful when the edge is sharp or uneven after cutting. In the final product, polished edges are not needed, and a matte finish is sufficient or desired. The glass for such processing must be protected on the entire surface except for the edge. Sandblasting then only affects the surface of the glass edge.

Matting glass is nothing more than sandblasting the surface of the entire glass item or figurine. This creates a so-called Frosted Glass in a white-gray color.